Interior Design Alliance

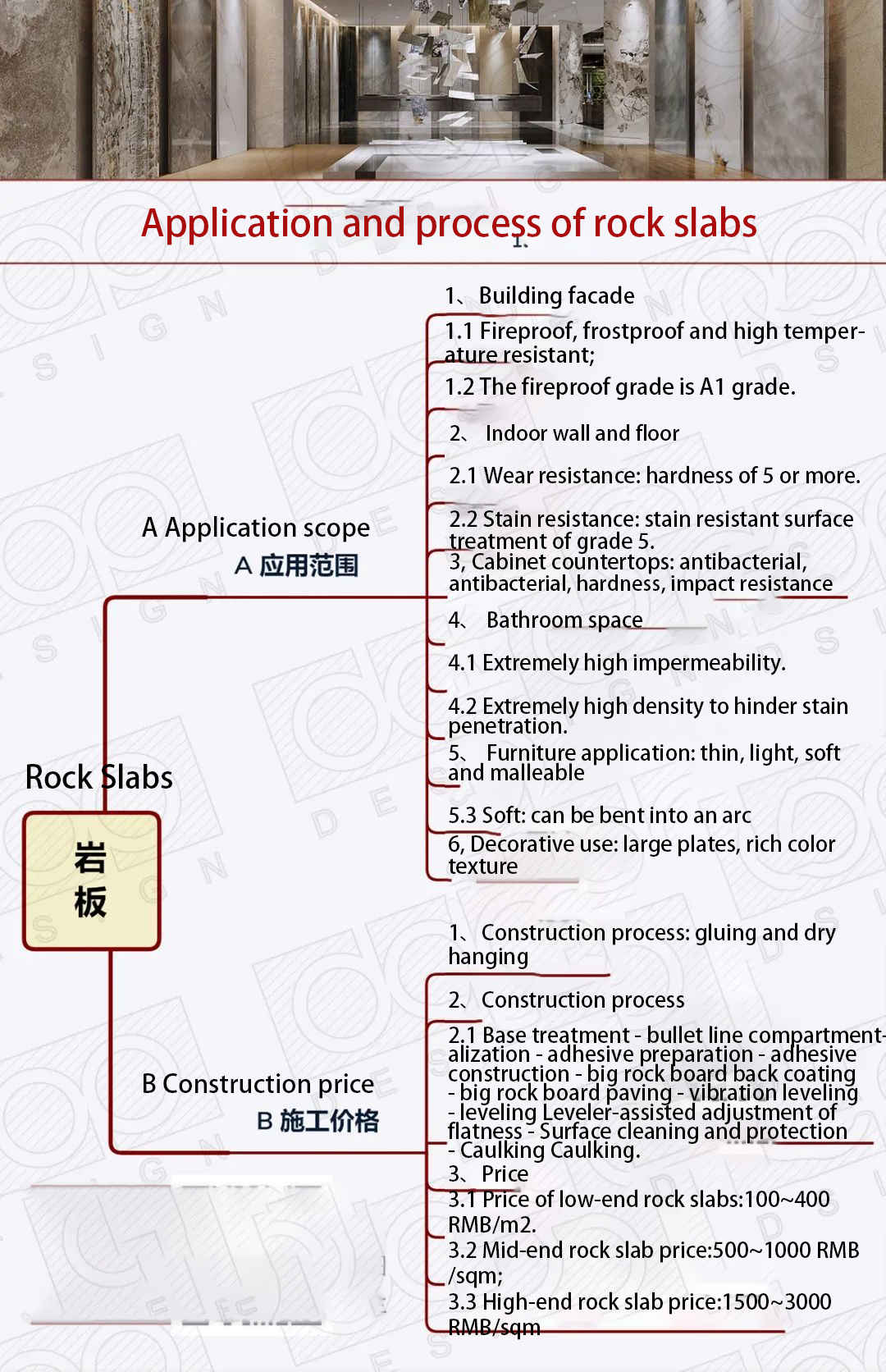

Ceramic rock slab is made of natural raw materials through a special process, pressed with the help of over 10,000 tons of presses, combined with advanced production technology, and fired at over 1200℃. It can withstand cutting, drilling, grinding and other processing processes of new porcelain material of oversized size. Ceramic rock panel is mainly used in the field of home and kitchen panels.

In recent years, with its excellent physical properties, rock slabs have become the supernova of environmental protection materials and are highly respected and loved by designers.

As a new species in the field of home furnishing, rock panel home has large specifications, strong shapeability, various colors, high temperature resistance, wear and scratch, anti-permeability, acid and alkali resistance, zero formaldehyde, environmental health and other characteristics compared with other home furnishing products.

Based on all these advantages, rock panel is widely used by many home lovers in building facades, indoor floors, walls, bathroom spaces, cabinet countertops, furniture panels and other fields. So how is it? You look down to.

01.

Building facade

Based on the physical properties of fire resistance, frost resistance and high temperature resistance, rock panel is a very friendly choice for building facade material, and the fire resistance grade is A1.

Its anti-frost property comes from the strict anti-frost test during the production process, and it is resistant to -80℃ low temperature, thus it can resist cold weather without any damage.

02.

Indoor wall and floor

Rockboard itself has the characteristics of stain resistance and wear resistance, so it is quite suitable for indoor walls and floors.

1、Wear-resistant

Rockboard is generated at high temperature and pressure. Its hardness is above grade 5. It will not be scratched or damaged by a steel knife, so it is very wear-resistant for flooring!

2、Stain resistance

Under the compressive force of the large tonnage press, the rock slab has a high degree of denseness and has an independent nano-protection layer. It has 5 levels of stain-resistant surface treatment, stains are not penetrated. If it is dirty, a wet towel wipe, it can be easily fixed.

03.

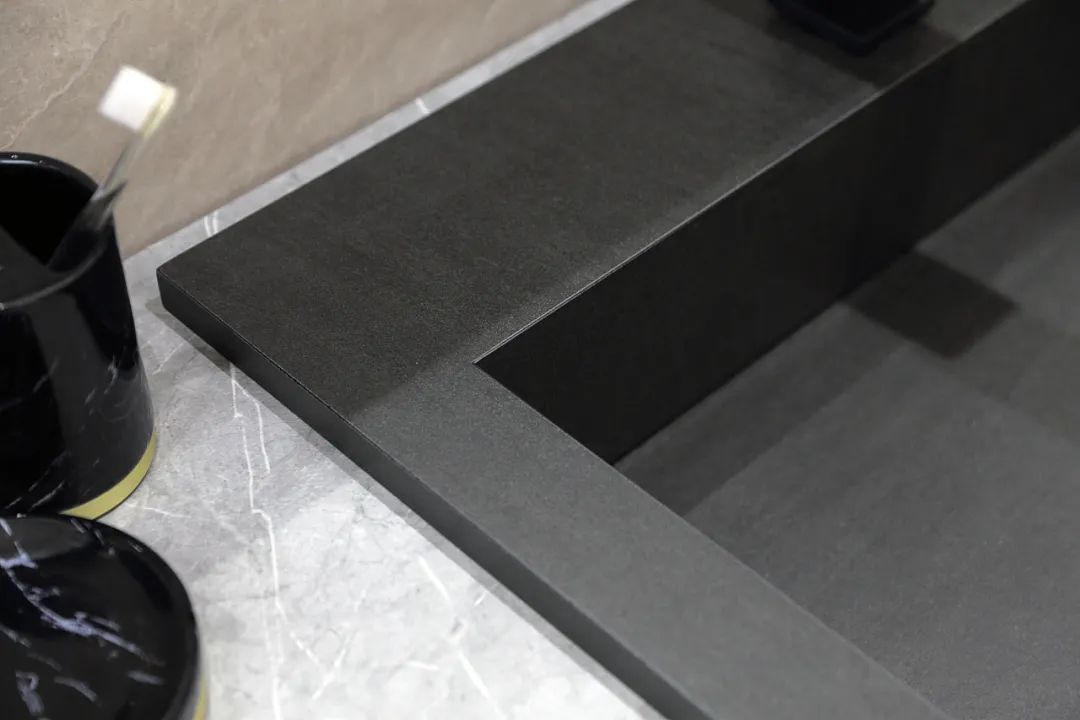

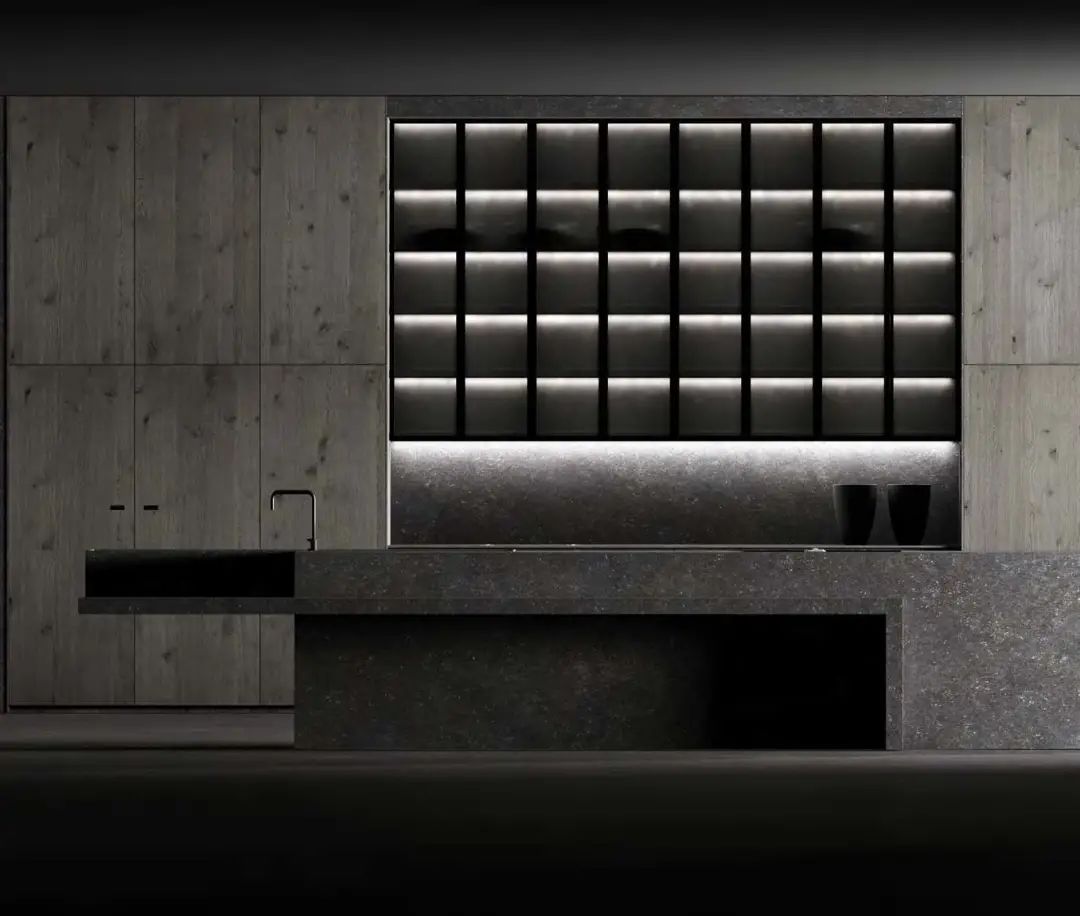

Cabinet countertop

Rockboard is also used for cabinet countertops because of its antibacterial, antibacterial, hardness and impact resistance properties.

1、Hardness and impact resistance

The thickness of rock slab ranges from 3mm to 20mm. Even the thinnest rock slabs are very hard. It can resist hardness and impact.

The impact resistance of 6mm thick rock slab is equivalent to 35mm granite, even if you chop meat or cut bone on the rock slab, there will be no fracture.

2、Anti-bacterial and anti-bacterial

Rock slab has a food-grade surface, which is healthy and environmentally friendly. It has passed NSF certification, so you don’t have to worry about mold invading the blank. (NSF is the designated collaborating center of the World Health Organization in food safety and drinking water safety and treatment.)

04.

Bathroom space

Rock slate is extremely impermeable. It is the best tile on the market today. It has a minimum permeation rate of 3,000 parts per thousand, while rock slate has a permeation rate of 2,000 parts per million. You can apply it to the bathroom space with complete confidence.

In addition, the extremely high density of rock slate hinders the penetration of stains. You won’t have to worry about sewage and stains seeping into the stone, and it’s also easy to clean.

05.

Use in furniture

In the actual use, rock slab also fits well with the furniture, and the characteristics of lightness, thinness, flexibility and plasticity are also its essence.

1、Thin

The thickness of rock slab countertop is only 1/3 of traditional tile.

2、Light

The average weight of traditional tiles is 23~27kgs/㎡, while the average weight of ultra-thin rock slabs is only 7kgs/㎡.

3、Soft

The unique size of 3mm thickness 1.2×3.6m, its softness can be bent into an arc.

4、Strong plasticity

Rock panel can be drilled, polished, cut and other deep processing, suitable for making various shapes.

06.

Decoration use

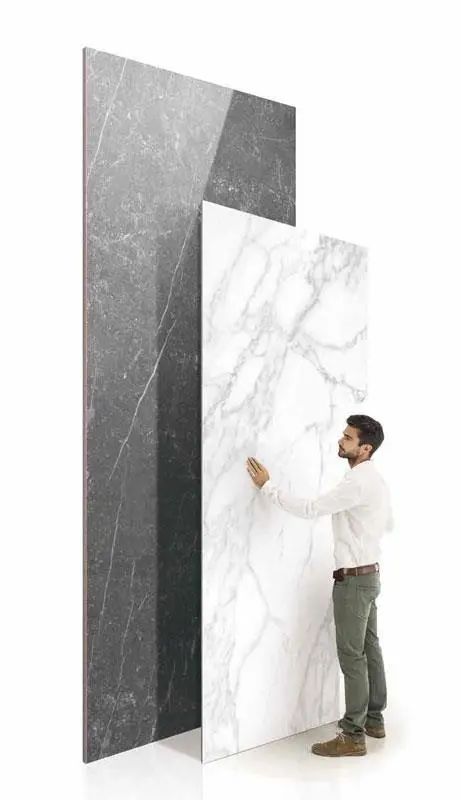

1、Large plate

The size of rock panel is wide, which is more than enough for backdrop decorative wall alone, and the regular sizes are

3600×1200mm×(3mm、6mm), suitable for wall, finish, kitchen cabinet door panel.

3200×1500mm× (6mm, only a few colors have 3mm), suitable for wall, finish, kitchen cabinet door panel).

3200×1600mm×(12mm, 20mm), for kitchen cabinet countertops, table tops, floors.

2600×1200mm, 2600×1500mm, used for project customization only.

2、Rich color texture

Rock board color texture is rich: pure color, volcanic rock, stone grain, cloth grain, wood grain, classic original stone, luxury stone and other textures are available, but also on the surface of the touch and light.

△Volcanic rock series

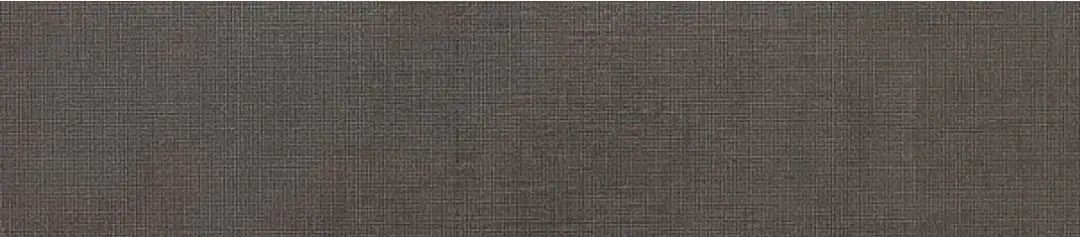

△Cloth grain series

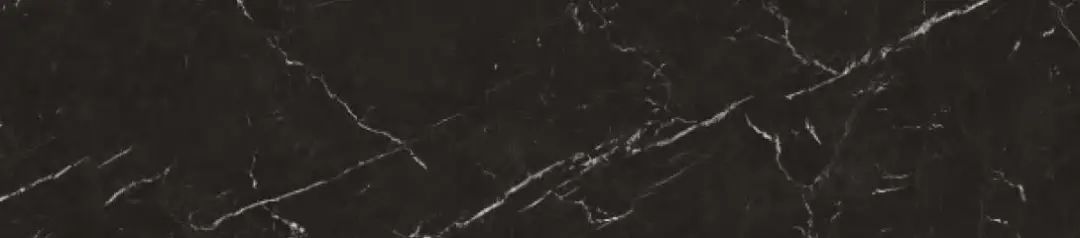

△Stone grain series

△Wood grain series

△Original stone series

△Luxury stone series

△Matte surface

△Silk surface

△Wash grain surface

△High-gloss surface

△Nano-soft surface

△Nano-soft surface

07.

Construction of rock panel

There are two main types of rock slab construction techniques: gluing and dry hanging.

At present, the mainstream in the market is the manufacturer’s gluing process. During construction, using special instruments and tools, it can solve the problems such as large width of rock slabs, difficult to carry and unstable installation.

In addition, the project using honeycomb composite rock board dry hanging, is also very economical and stable practice. Which one should be used depends on the construction situation on site.

Rock slab paving process: grass-roots treatment → bullet line grading → adhesive preparation → adhesive construction → big rock slab back coating → big rock slab paving → vibration leveling → leveling device to assist in adjusting the levelness → surface cleaning and protection → caulking treatment.

There are also 2 types of rock slab dry hanging: aluminum honeycomb composite rock slab dry hanging and gluing method + stainless steel corner piece fixing.

(For details of rock panel construction process, we will not list them all here.

08.

Rock panel price and brand

Finally, let’s take a small summary.

WOWOW Faucets

WOWOW Faucets

您好!Please sign in