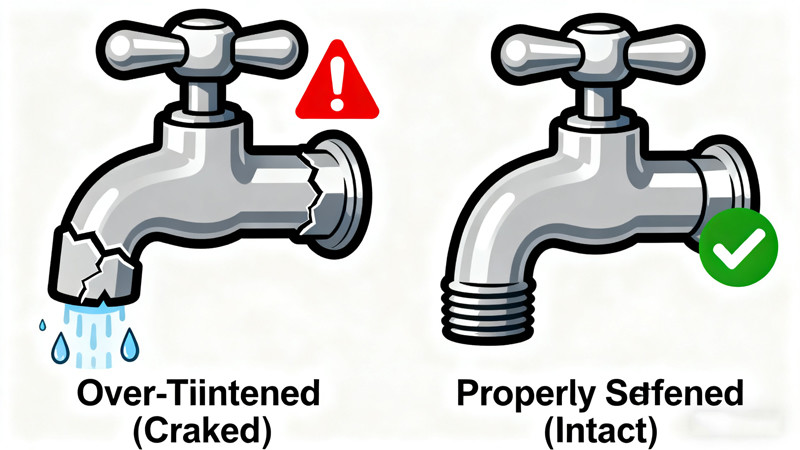

When installing or repairing a faucet, it’s natural to want everything to feel sturdy and secure. After all, no one likes a loose fixture that wobbles or leaks. But there’s a hidden danger many DIYers—and even some professionals—fall into: over-tightening. While it might seem like tightening a faucet as much as possible will prevent leaks, the opposite is often true. Over-tightening can strip threads, crack components, and create long-term plumbing issues that cost far more to fix than the original job.

In this post, we’ll explain why over-tightening is a common mistake, how to recognize it, and—most importantly—how to avoid it while ensuring your faucet installation is both tight and leak-free.

Why Over-Tightening Faucets Is a Problem

Over-tightening can cause several types of damage depending on which part of the faucet you’re working on. Each connection—whether it’s a compression fitting, threaded joint, or mounting nut—has a designed pressure tolerance. Once you exceed that, problems start to occur.

- Stripped Threads:

Most faucet parts use brass, copper, or stainless steel fittings, which are softer metals. When you apply too much torque, you can strip the threads, making it impossible for the fitting to grip properly. Once stripped, even plumber’s tape or sealant won’t fix it—you’ll likely need a replacement part. - Cracked Components:

Many modern faucets use plastic or ceramic cartridges and internal parts. Excessive force can crack these delicate components, leading to leaks or total failure of the faucet’s internal mechanism. - Deformed Washers or Gaskets:

Rubber and silicone seals are designed to compress slightly to form a watertight seal. Over-tightening can crush or distort them, causing leaks over time as the gasket fails to return to its original shape. - Warped Mounting Hardware:

When you overtighten the nuts that secure the faucet to the sink or countertop, you risk bending the base plate or distorting the sink’s surface. This can lead to uneven pressure, gaps, and eventual leaks.

In short: tighter does not mean better—it often means trouble.

Common Areas Where Over-Tightening Happens

If you know where over-tightening usually occurs, you can take extra care during installation or repair.

- Supply Line Connections:

Whether you’re connecting flexible braided hoses or rigid copper pipes, supply line fittings are common victims of over-tightening. Hand-tight plus a small turn with a wrench is usually enough. - Faucet Base Mounting Nuts:

The nuts underneath the sink that hold your faucet in place don’t need to be cranked down like lug nuts on a car. They only need to be snug enough to keep the faucet from wobbling. - Cartridge or Valve Assemblies:

When replacing cartridges, people often twist them too tightly, thinking it’ll stop drips. However, most cartridges seal with O-rings, not pressure, so overtightening can actually damage the seals. - Aerators:

Even faucet aerators are sometimes over-tightened, leading to stripped threads or difficulty removing them for cleaning later.

Recognizing these vulnerable points helps you slow down and apply just the right amount of force where it’s needed.

How to Tighten Faucets Properly

Avoiding over-tightening doesn’t mean under-tightening. The goal is to find that “just right” amount of pressure—a balance that prevents leaks but avoids damage. Here are some techniques and best practices:

1. Follow Manufacturer Instructions

Every faucet is designed differently, and manufacturers provide specific torque or tightening guidelines for their models. Always read the instructions before starting. For example, a cartridge may need only hand-tightening, while a supply nut might require one-quarter turn beyond hand-tight.

2. Use the Right Tools

Using the correct wrench or basin tool helps control the amount of force you apply. Adjustable wrenches and basin wrenches can be tricky because they give a lot of leverage, making it easy to overdo it. Try using a shorter-handled tool when possible—less leverage means less risk of over-tightening.

3. Tighten by Hand First

Always start connections by hand. This ensures that threads align properly and prevents cross-threading. Hand-tighten until you feel resistance, then use a wrench for only a small additional turn—typically one-quarter to half turn.

4. Use Plumber’s Tape (Teflon Tape)

Plumber’s tape can help create a better seal with less force. When applied correctly (wrap clockwise around the male threads two or three times), it lubricates the threads and reduces the need for extra torque.

5. Test for Leaks Before Final Tightening

After connecting everything, turn on the water slowly and check for leaks. If you notice a small drip, tighten the connection slightly—just enough to stop the leak. It’s better to tighten gradually than to overtighten all at once.

6. Use Torque Guidelines if Available

Some professionals use torque wrenches to apply the exact pressure recommended by the manufacturer. While this isn’t necessary for every job, it’s an excellent practice for precision installations.

Pro Tips for Safe Faucet Installation

- Support the Faucet Properly:

When tightening under the sink, hold the faucet body steady from above. This prevents twisting stress that can crack the base or damage internal seals. - Avoid Power Tools:

Power drivers or impact wrenches are a big no-no in faucet installation. They’re designed for heavy-duty tightening and can easily destroy delicate fittings. - Inspect Gaskets Before Tightening:

Make sure all rubber washers, O-rings, and gaskets are clean and properly seated. A misaligned gasket might tempt you to overtighten to stop leaks. - Use Lubricant for Threaded Parts:

A small dab of plumber’s grease on metal threads can help prevent seizing and allow easier removal later, reducing the temptation to overtighten. - Remember: Snug Is Enough.

The most important rule is simple—stop tightening when the connection feels snug and secure. If it’s not leaking, it’s tight enough.

The Cost of Over-Tightening

The damage caused by over-tightening can be surprisingly expensive to fix. Stripped threads may require replacing the entire valve body. Cracked faucet bases might necessitate a new faucet altogether. Even worse, if over-tightening causes leaks inside cabinets or behind walls, you could face water damage and mold growth.

Spending an extra minute to tighten carefully is far cheaper than paying for replacement parts or a plumber’s visit later.

Conclusion

Over-tightening is one of the most common mistakes in faucet installation—and one of the easiest to avoid. The key is understanding that plumbing components are engineered to seal through design, not brute force. Hand-tight, plus a gentle wrench turn, is almost always enough.

By using the right tools, following manufacturer guidelines, and taking a patient, step-by-step approach, you’ll achieve watertight connections that last for years—without the costly consequences of overtightening.

So next time you’re tempted to give that nut or fitting “one more turn,” remember: snug, not strong, wins the day.

WOWOW Faucets

WOWOW Faucets