How to Identify Faucet O-Ring Sizes

A faucet may look simple on the outside, but inside it relies on several small components to prevent leaks and deliver smooth operation. Among these components, the O-ring is one of the most important. It creates a watertight seal, prevents handle wobble, stops drips, and ensures smooth movement of the faucet spout. Yet when an O-ring wears out or cracks, water can leak from the base, handle, or spout. Replacing it is usually cheap and easy—if you can identify the right O-ring size. Choosing the wrong O-ring leads to poor sealing, installation issues, and repeat repairs. In this guide, you’ll learn how to identify faucet O-ring sizes accurately, which tools to use, and how to avoid common mistakes.

Why O-Ring Size Matters

O-rings work by creating compression between two surfaces. For an O-ring to seal properly, three dimensions must fit precisely:

- Inside Diameter (ID)

- Outside Diameter (OD)

- Cross-Section Thickness (CS)

If any of these dimensions are incorrect, the O-ring may:

- Leak

- Stretch too much

- Compress unevenly

- Crack prematurely

- Fall out of its groove

Correct sizing ensures smooth faucet movement, long-lasting sealing, and leak-free performance.

Signs You Need to Identify or Replace Your Faucet O-Ring

Before learning how to size one, make sure an O-ring is actually the cause of your issue. Common symptoms include:

- Water leaking around the spout base

- A faucet spout that rotates too easily

- Stiff or squeaky handles

- Water dripping from under the handle

- A spout that wobbles or has too much play

- Visible cracks in the O-ring

If you notice any of these, it’s time to identify the correct replacement.

How to Identify Faucet O-Ring Sizes

There are several reliable ways to determine O-ring dimensions. Below are the best methods, ranked from easiest for beginners to most precise for professionals.

Method 1: Use the Original Faucet Manual or Exploded Diagram

The simplest method is checking the faucet’s documentation.

Most brands list O-ring sizes in:

- The installation guide

- The replacement parts diagram

- The model’s product page

Look for dimensions such as:

- ID (e.g., 17 mm)

- CS (e.g., 2.5 mm)

- OD (e.g., 22 mm)

- Part numbers like “#011 O-Ring” or “#116 O-Ring”

Pros:

- No measurement mistakes

- Ensures exact fit

Cons:

- Manuals may be lost or unavailable

- Some brands don’t list measurements

If you give me your faucet model, I can help find the correct O-ring size.

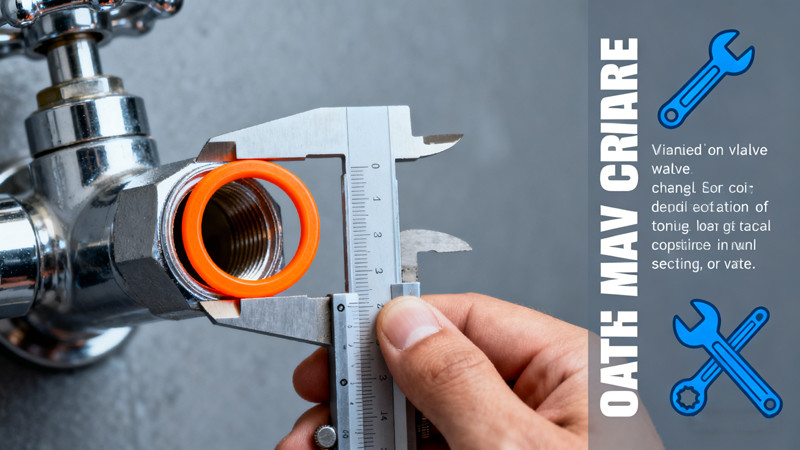

Method 2: Measure the Old O-Ring Directly

This is one of the most accurate methods—if the old O-ring isn’t too worn or stretched.

Tools Needed:

- Digital caliper (preferred)

- Ruler (less precise)

Measure 3 Key Dimensions:

1. Inside Diameter (ID)

Gently stretch the O-ring and measure the inner hole diameter.

This is the most important dimension.

2. Cross-Section Thickness (CS)

Measure the thickness of the rubber from inner edge to outer edge.

Common faucet CS sizes include:

- 1.78 mm

- 2.4 mm

- 3.1 mm

3. Outside Diameter (OD)

Calculated by:

OD = ID + (2 × CS)

Pros:

- Accurate

- Works for most O-rings

Cons:

- Old O-rings may be swollen or flattened

- Measurements can be slightly off if worn

If the old O-ring looks misshaped, use Method 3 instead.

Method 3: Measure the O-Ring Groove on the Faucet Spout

If the O-ring is damaged, hardened, or missing, measure the groove on the faucet spout instead. This is often more precise than measuring the rubber itself.

Steps:

- Remove the faucet spout.

- Clean the groove thoroughly.

- Use a caliper to measure:

- Groove diameter → gives the O-ring ID

- Groove depth → helps match the cross-section

- Groove width → ensures the O-ring won’t bind

Pros:

- Perfect measurement even with bad O-rings

- Doesn’t rely on guessing

Cons:

- Requires caliper

- Requires access to the spout or handle assembly

Method 4: Compare with a Metric/Standard O-Ring Chart

O-rings follow standardized sizes such as:

AS568 (Imperial sizes)

Common in American faucets (Moen, Delta, Peerless).

O-ring numbers like 013, 014, 117 indicate standardized sizes.

Metric O-Rings

More common in European and Asian faucets.

How to Use the Chart:

- Measure ID and CS

- Match them to chart values

- Choose the closest exact match

Pros:

- Works for nearly any faucet

- Helps avoid non-standard O-rings

Cons:

- Requires careful measurement

Method 5: Take the O-Ring to a Hardware Store

Most hardware stores carry O-ring sizing boards or bins where you can test-fit O-rings.

Steps:

- Bring the old O-ring.

- Match it on their sizing board.

- Select the closest standard size.

Pros:

- Easy for beginners

- No tools required

Cons:

- Some stores only carry limited sizes

- Can be hard to match worn O-rings

Tips for Choosing the Correct Replacement O-Ring

1. Don’t choose an O-ring that feels “almost right”

If it’s too tight, the spout won’t move.

If it’s too loose, it will leak.

2. Use faucet-safe materials

Choose:

- EPDM (best for water)

- Nitrile (good alternative)

- Avoid silicone O-rings (too soft for most faucets)

3. Lubricate the O-ring before installation

Use plumber’s grease, never petroleum jelly.

Lubrication prevents:

- Tearing during installation

- Friction wear

- Stiff spout movement

4. Replace all O-rings at once

If one has failed, the others may be worn too.

Final Thoughts

Identifying the right O-ring size for a faucet doesn’t have to be confusing. With a few simple tools—like a caliper or a sizing chart—you can measure the O-ring or the faucet groove and match it accurately. Whether you use the old part, check the manual, or bring it to a hardware store, the key is precise measurement. The better the fit, the longer your faucet will stay leak-free and smooth-operating. By choosing the correct size and installing it properly with the right lubricant, you can restore your faucet to like-new performance and avoid unnecessary leaks or repairs.

WOWOW Faucets

WOWOW Faucets